Growers help to bring clean water and hygiene education to communities in need

Last year, we shared a story of a partnership between Grochem and Unicef NZ to support a ‘water, sanitation and hygiene in schools’ (WASH) project in the Penama province, in Vanuatu starting back in 2017.

The WASH in Schools project aims to reduce sickness and arm children with safe hygiene practices which they can carry from school into their homes, with a flow-on effect that will benefit the community for generations to come. It means installing safe water and sanitation equipment in schools across the Penama province of Vanuatu, and instilling a culture of hygiene and sanitation practices, so that children can stay healthy while going through school and complete their education.

Last year Grochem raised $111,000 for the project with some additional contributions from the Norway based company Nordox, and the NZ government. To date it brings the project fundraising efforts over the last two years to $213,000. This year marks the third year that Grochem will be fundraising for this initiative, and thanks to growers in the industry purchasing Nordox, a disease control solution, they are confident that it will be their most successful year yet.

So why did Grochem decide to team up with Unicef NZ?

With hundreds of Recognised Seasonal Employees (RSEs) coming from Vanuatu every year to assist NZ growers with their harvest periods, Grochem recognised the value they provide the industry. These RSEs are leaving their families for long periods of time every year to help our horticulture sector get through one of the most challenging times of the year, and so Grochem wanted to support their communities back home.

One thing that really struck the Grochem team, was that many of the children of the communities where the Vanuatu RSE workers came from, did not have some of the basic things we take for granted every day, namely access to fresh water and flushing toilets at school. When Grochem found out about the 5-year water, hygiene and sanitation Unicef NZ programme for schools in the Penama province, they knew that this was the project that Grochem should be involved in.

In this past year, it’s been especially rewarding for the team at Grochem to see that their fundraising efforts, and the support from growers, have allowed for a lot of progress to be made in the WASH in Schools programme. Just some of the developments include:

- Solid and safe ablution blocks have been built in many schools in the Penama province. This of course is a great improvement to the hole in the ground and a flushing bucket that many children are used to, and it means fewer children will be off school from illness due to poor sanitation.

- Some schools have been provided with basic facilities, which will be eventually replaced by proper ablution blocks. The new basic facilities allow children to get used to a new way of doing things while providing an immediate improvement in their way of life.

- Teachers, caregivers and students are being trained on how to improve their sanitation and hygiene practises through activities such as handwashing sessions and menstrual hygiene management awareness.

Grochem are pleased to work with UNICEF this year with the project to see what further improvements can be made to the lives of the Vanuatu children and their families.

If you’d like to support Grochem and the work that Unicef NZ is doing in Vanuatu, you can contribute through the purchase of Nordox, the best choice in quality copper, in the months of May and June from leading retailers. In doing so, $10 will go directly to the WASH in Schools programme, with the promise that many more school children will be able to benefit from having clean water and bathroom facilities, have greater attendance at school, and with an education, children are offered a way out of poverty.

$32,000 to support apple growing region’s hospice services

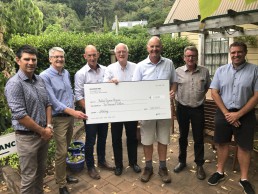

Manufacturers, distributors and customers from the apple growing regions of Tasman and Hawkes Bay came together to present donations raised for their local community hospices.

Leading horticulture manufacturer and supplier, Grochem, raised $22,000 for the Hawkes Bay’s Cranford Hospice, and $10,000 for the Nelson Tasman hospice through a campaign during October and November 2018 where they earmarked a proportion of sales of their leading apple thinning product, Meteor.

George McHardy, Managing Director of Grochem, said as a local business it’s important to our team to give back to local communities that support us – where New Zealand’s growers are.

“Over the past few years we’ve been raising funds for a Unicef NZ water sanitation project in Vanuatu, where many of our RSE workers come from to make the harvest possible, but we wanted to have an impact locally with those who support our business. For our team, hospice services just made sense,” says George.

It was the passing of a friend in the Hawkes Bay region’s apple growing community where many saw the unwavering support that hospice services provide to those needing end of life care.

“Saying goodbye to a friend sparked something inside our team. We wanted to do something for the communities where New Zealand’s apple growers and their families live and work,” said Grant Morrish, General Manager – Grochem.

The need for hospice support is clear. Nelson and Tasman’s population is getting older and growing, the demand for hospice services continue to grow too. In the past four years Nelson Tasman Hospice has seen a significant increase in referrals for their services. At any one time they are looking after 180 patients in the community.

In the Hawkes Bay, the Cranford Hospice made more than 23,730 contacts with 853 patients, either at home, on the phone, or in their inpatient unit in the last year.

Behind these numbers are individual people and their families who were cared for by the hospice team. This is enabled through the support they have from their communities and through organisations such as Grochem and their customers.

The hospices often undertake projects with no government funding, or need to top up their operational budget by several millions to continue providing this vital service.

Grant Morrish said the funds raised in both regions was a joint effort between the regions’ growers and distributors, and it was humbling to see them come together for their community.

Cranford Hospice – Hawkes Bay

Left to right – Back Row: Tony Waites – Mr Apple, Chris Herries and James Cropper – Horticentre, Peter Melville – Fruitfed Supplies, Mike Annand – Farmlands, Greg Evans – Grochem. Front Row: Shelly Covell – Hospice advocate, Grant Morrish – Grochem, Janice Byford-Jones – Cranford Hospice, George McHardy – Grochem, Richard Rutherford – Fruitfed Supplies

Nelson Tasman Hospice

Left to right: Mark Milne – Fruitfed Supplies, Paul McIntyre – Nelson Tasman Hospice, Grant Morrish – Grochem, Nelson Tasman Hospice CEO Frans Dellebeke, Gary Marshall – Grochem, Dave Stephens -Farmlands, and Chris Bins – Tasman Crop Protection.

Supporting our communities in their time of need

In some of the final days of saying goodbye to loved ones many of us will have seen the genuine empathy and kindness of hospice care, and understand and appreciate the critical work that they do in our communities.

Hospice care services support families and whānau during one of life’s most challenging times, and help people make the most of the time they have left by supporting patients to live every moment – no matter where they are – whether it be at home, an aged care facility, or at the hospice itself.

Hospice teams have a unique approach, known as “palliative care” – the focus is on the whole person, in a spiritual, emotional and social sense, as well as dealing with physical challenges, and is provided to every patient regardless of age, ethnicity, means or religion.

That level of support requires an extraordinary number of volunteers and staff. The Cranford Hospice in Hawkes Bay for example has over 400 volunteers and 85 staff looking after over 750 patients each year. It really is a community coming together to support people in their final moments.

As a free service provided to anyone with a life-limiting illness – funding is always challenge. Much of their funds comes from government health budgets, but the shortfall (several millions each year for each hospice) comes from fundraising.

That is why Grochem, New Zealand’s only owned and operated manufacturer of innovative solutions for growers, have launched a campaign to support hospice care services in the communities of our nations’ apple growers – Hawkes Bay and Tasman.

Throughout the months of October and November Grochem will donate $35 to the Cranford and Nelson Tasman Hospice for every 1kg of Meteor sold, a leading apple thinning agent.

Grochem have also set up a page on their website for those who are not users of an apple thinning agent, where they can still participate by pledging their donation.

Hospice care is highlighted on one day each year throughout the world to raise awareness of what hospice care is. This year the World Hospice and Palliative Care Day is on 13 October with the theme “Because I Matter”, focusing on the individual needs of each person.

Doing the right thing by the communities we live and work in, and for the people who have an impact on us, is important to us at Grochem. We’d love for you to be part of that too.

You can pledge a donation on their website by emailing grant@grochem.com or visiting nz.grochem.com/projects/supporting-communities/

Published in The Orchardist

What’s the answer to achieving the right balance of boron?

Boron is one of the essential trace elements that every plant relies on and is well known to be a valuable resource ensuring a plant’s healthy leaf development, flowering, reproductive cycle and seed development. But, in New Zealand our soils are largely deficient in this critical building block.

Boron fertilisers generally come in the form of either sodium borate (highly soluble), calcium borate (extremely insoluble), or magnesium borate, which sits relatively in the middle. Most of the boron fertilisers in the New Zealand market are based on sodium borate, or Ulexite.

Growers using sodium borate face two key problems. Firstly, boron that is not immediately taken up by the plant leaches away almost as quickly as the water because of its high solubility and can often result in a boron deficient plants. Secondly, but perhaps more critically, if boron is released too quickly it can result in boron toxicity.

Due to the challenging balance between applying too little or too much, growers will usually apply boron in small amounts several times a year to achieve the necessary constant supply to plants.

The answer to achieving the right balance of boron lies in Argentina where an extremely rare magnesium and calcium borate rock occurs naturally. It’s called OrganiBOR, a rare mineral that has been supplying boron requirements to the New Zealand market for over 10 years, with great success for growers.

OrganiBOR is a BioGro certified fertiliser and can be used on any crop, including all organic crops, and can be applied at any time of the year. Growers using OrganiBOR have been seeing significant results compared to the other boron products on the market.

Manager of Barewood Station of Lonestar Farms in Otago, Marty Deans, says “for the last 5-6 years Lonestar Farms have used OrganiBOR over their 800 hectares of brassica, fodderbeet crops and lucerne. OrganiBOR has assisted in growing healthy crops year on year with an observed reduction in brown heart. The lucerne is also reaping the benefit of the higher boron levels that are easier to access.”

Unlike sodium borates, OrganiBOR can be applied to crops and pasture just once every 12 to 24 months depending on desired outcomes, climate and soil conditions.

The calcium/magnesium borate chip releases boron at a similar rate to which most plants take up boron from the soil, it therefore eliminates the risk of boron toxicity or creating boron deficient environments.

Throughout the growing season OrganiBOR will release a stable supply of boron to the crop or pasture, a critical factor to plant growth. This continuous supply allows for higher dry matter yields and better-quality crops and pasture, as well as a sustainable, effective and economical solution for crop management.

Published in Southern Rural Life

Grochem celebrates 25 years

By Rose Mannering in The Orchardist

Grochem celebrated its 25th year anniversary in Havelock North on June 27, the sole remaining New Zealand-owned chemical company.

From humble beginnings supplying nutritional products for flower production, to a world renowned chemical supplier, managing director George McHardy says the company has plenty to celebrate.

Research and development of new sustainable products is the cornerstone of what Grochem does, he says. With 48 registered agrichemicals and many nutrition formulations here, 23 Australian registrations, four in South Africa and two under development in Chile, Grochem is totally committed to its product stewardship. Memorable firsts in that time included a world first registration for:

- Ammonium Thiosulphate or Thin-it for primary thinning of apples in 2003;

- Blossom Bless, for fire blight control, was the first biological agent to be registered in 2006 under the new HSNO Act;

- Ambitious gained a world first label claim for fruit sizing of apples in 2010, followed by registration registration for Psa suppression in kiwifruit;

- Nordox gained registration for Psa control in 2013;

- Bapsol 100 thinning product was introduced in 2011;

- Meteor was registered in 2015, the “revolutionary secondary thinning chemistry for apples”.

Since a local buy-out of Grochem 12 years ago, the company has experienced rapid growth. “We are now the only independently owned and operated company that still manufacturers, imports and develops a range of nutrition and crop protection products specific to our environment,” he says.

Relationships with multinational partners have been key, as some do not see New Zealand or Australia as being big enough in their own right for them to be based here. They generally develop products for the big markets (cotton, soybeans or corn), and smaller horticulture based markets are not recognised by them. “However, some of the molecules may have a unique fit in parts of our growing systems which we set out to identify.”

George says the supply environment is changing, with considerable rationalisation. The main country of manufacture, China, has been shutting down polluting factories, placing pressure on supply and consequently price.

“Being an export dependant nation, we must make sure that input products used by our growers are fit for the international stage. After a serious industry wakeup call last year in pipfruit (not by our company I might add), we need to be wary of unfamiliar suppliers and their offering!”

Thorough testing under local conditions is needed to ensure there are no surprises in the field.

Grochem has participated in the massive growth that horticulture has been, from the early 1990s of $700-million exports to today’s figure approaching $3.6-billion. George warned the industry needed to remain agile and adapt with haste if need be.

Giving back

Two years ago, Grochem launched a Nordox campaign to support RSE (Recognised Seasonal Employers) from Vanuatu. For every box of Nordox sold during May and June, $10 was donated toward a UNICEF project to supply fresh water and sanitation to 150 schools in the Penama region. General Manager Grant Morrish says Grochem donated over $20,000 to UNICEF last year. The New Zealand government also got in behind the UNICEF WASH project and for every dollar raised by Grochem, contributed a further $4.

Based on last year’s success, the project is being re-run this year, and Grant is hopeful similar levels will be reached.

A second programme this year will raise funds for hospices in Nelson and Hawke’s Bay, with $35 per kilogram from the sale of Meteor during October and November donated to the hospice cause.

Grochem - Committed to quality

Ensuring a high-quality effective product for our customers – every time

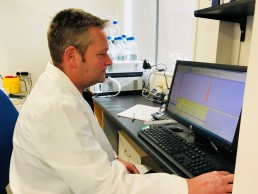

Each morning Grochem’s chemist Martin Turver puts on his lab coat and gets to work. He’s looking for several things through his product and raw material testing, but most importantly, he’s checking that everything going in and out of the Grochem manufacturing site is what it says it is, right down to the last decimal point.

Over the last 25 years Grochem has evolved from a business that supplied product as and when needed, to become a key supplier for Horticulture producing 10 times the amount we used to. Our value in the market has certainly grown significantly since the starting days of 1993, and the quality of our products have been a major contributor to Grochem’s success, so to continue providing this value it was imperative that our processes and quality control evolved along with it.

Today, everything from the raw materials sourced from across the globe to the ready-to-use product that leaves the factory, Grochem exercises above-industry-standard internal control methods and processes, and we’re always innovating in how we achieve this.

This commitment to a being best-in-class for quality control gives both us and our clients the utmost confidence in our products.

To do this, we employ four core steps in our manufacturing process, including:

- Raw material specification testing

- Robust risk analysis

- Independent product testing

- Final product dispatch testing

- RAW MATERIAL SPECIFICATION TESTING

It starts with the raw materials – the quantity and active ingredient need to be exactly to specification – we won’t settle for anything less. As raw material arrives at the factory, it won’t enter the manufacturing plant until it has been tested and approved for use. If it’s under spec, it doesn’t enter the manufacturing plant, and is usually sent back.

As raw materials are added into the final product, each raw material has been approved and ticked off.

2. ROBUST RISK ANALYSIS

Grochem has designed its own in-depth risk analysis matrix which identifies the top 16 products with a risk-factor (compared against their other products) of containing non-product residues. We take into consideration multiple factors to determine our top risk products, including:

- Whether the manufacturer or supplier is a single or multi product supplier

- What other products the supplier manufactures and the likelihood of contamination

- The quality control capabilities of the manufacturer or supplier

The risk matrix helps to determine what products we send for independent rigorous contamination testing.

3. INDEPENDENT TESTING

The products identified from our risk analysis are then sent for more sophisticated testing at a specialist lab in Australia for contamination screening of some 45 compounds. New Zealand doesn’t yet have the capability to test to the level of specificity that we need, so to achieve this level of confidence in our product, sending it off-shore is must.

4. FINAL DISPATCH TESTING

During the process of manufacturing, the product is sampled and tested for quality. Once the product passes the specifications, Martin will then authorise the production team to pack/bottle and label. It’s only at this point the product is prepared for dispatch.

Each batch sample is stored for a minimum of 2 years in Grochem’s designated sample library.

Nothing leaves the factory without being tested and signed off by either our on-site chemist Martin, or our site operations manager Marcus.

The quality of our products is one of the most important aspects of our business, and to commit to a high-quality effective product every time, requires a specialist team. Grochem hand-picks each member of our team for the specialist skills they bring to the business, which gives our customers end-to-end quality from source, manufacture, distribution and sales.