Clean water + education for healthier RSE communities

Four years on, Grochem continue to support the UNICEF water sanitation and hygiene (WASH) in schools program in Vanuatu.

The lack of clean water and proper sanitation affects the lives of 8,100 children of the Penama region. Diarrhoea is the leading cause of childhood deaths in the Pacific and poor water and sanitation is linked to stunting in children’s growth.

But the work being done with the Vanuatu UNICEF WASH project over the past four years has meant a tangible positive change in the region. UNICEF along with the Vanuatu government have been working to set up programmes that educate many of the schools and communities in the importance of proper hygiene methods with toilets, along with preparing and eating food.

Vanuatu Penama Schools are asked to prepare WASH improvement plans, which they liaise with UNICEF and the Vanuatu Ministry of Education staff for guidance. The goal by the end of this year is to have all 83 schools with access to clean water and latrine facilities.

The local communities of the schools are taught how to build and maintain the latrines, which supports the community in taking responsibility for the care of these facilities. However, it is the education phase which is the most important to change behaviours when it comes to hygiene practice.

Since the WASH program has been implemented:

- 75 of the 83 schools have good hygiene behaviours, leading to improved health outcomes.

- Absenteeism rates have reduced.

- Literacy and numeracy for students has increased

When you take into consideration tropical cyclone Harold in 2020 and the 2017 Ambae Island volcanic eruption, this result is a great achievement by Vanuatu and their communities, and one that Grochem is very proud to have been involved with over the last four years. New Zealand’s Ministry of Foreign Affairs and Trade’s support for this project has contributed an additional $4 for every $1 raised, bringing the Grochem and MFAT combined support to over $300,000.

A very big and genuine thank you to our customers for their continued support. We would otherwise not be able to provide this much needed help to the many families of the Recognised Seasonal Employees (RSEs) from Vanuatu. The RSE’s contribute a lot to our horticulture community and our team at Grochem believe that this is a small way in which we can give back to them.

Innovative products for specific needs

Innovative products for specific needs

Written by Richard Loader

Research and development is all about the future, says Grochem’s managing director George McHardy.

“If you don’t have new products coming through you end up becoming a generic player. Our focus has been on niche, safe soft chemistry that’s more environmentally friendly and sustainable. There’s a strong biological and organic focus to what we do. We also outsource a lot of trial work with independent providers to prove our product in the paddock.”

George explains that because 90% of what New Zealand produces is exported, whatever Grochem produces and supplies must be fit for where ever that produce is destined for.

“A lot of apples will end up in Asia, Europe or the US and we have to ensure anything we supply to the apple industry fits in with wher- ever the product is going to. That’s why quality control is paramount in what we do.”

Proud to be Kiwi owned and operated, over the last 27 years Grochem has evolved to become the leading supplier of innovative, sustainable options for growers—including plant nutrition, insecticide, fungicides and plant growth regulators.

Grochem’s laboratory, manufacturing fa- cilities and head office is based in Porirua, pro- viding close proximity to the state highway for northbound transport and access to Welling- ton port for South Island and export dispatch.

“Being local we can develop and manufacture product for our customers within a very short time frame and we can make decisions quickly.

“As long as we have the raw materials here we can manufacture specific products for a client overnight or within day or two. Many of our competitors are importing finished goods from around the globe that have major lead times and/or products that are bulky in nature.”

Predominantly a horticulture based company, Grochem’s biggest region is Hawke’s Bay, but also operates throughout all of the main growing regions in New Zealand.

“The products we develop and manufacture are specific for local conditions and that gives us a point of difference. We have products that are more specific to soil conditions in Hawke’s Bay, for example, versus somewhere else.

“We also represent 14 multi-national partners with unique or novel products.

“We have an organic boron product from an Argentinian mine, which is used on arable brassica crops here and in Australia. We’re the largest organic input providers within the commercial sector in New Zealand.”

Along with a small office in Hawke’s Bay, Grochem’s strong technical team is located in the country’s key growing areas to meet with local growers and large grower corporates and help train local distribution staff.

“All our products are distributed through businesses like Wrightsons / Fruitfed Supplies, Farmlands and the Horticentre Group.

“They have technical specialists who go out and service the customer and growers in the paddock.

“A lot of our ideas for new products will come from a grower who sees an opportunity or has a problem growing a certain crop.”

In 2017 Grochem won the Deloitte Fast 50 Fastest Growth in Agribusiness for the Lower North Island and Wellington Region.

Fire Blight management best practice

Late bloom removal in apples & pears using Thin-It (ATS)

Temperature conditions in late October and into November are frequently conducive to fire blight bacterial build up and infection of late blossoms. Late blossom infections play a significant part in establishing fire blight in orchards. Even a few overwintering cankers can become significant inoculum sources for fire blight epidemics in subsequent seasons. Newly planted blocks usually flower later than established trees, so are especially at risk to fire blight.

Removal of late blossom is relatively easy and should become an established part of an integrated fire blight management programme.

The most proven late bloom removal tool is the blossom thinner Thin-It (Ammonium Thiosulfate, ATS).

There is an extensive body of experience in using Thin-It in NZ for late bloom removal in apples and pears and the following bullet points summarise this experience.

- Late bloom is relatively easy to remove. Apply Thin-It at label rates of 1.5% (1.5L per 100 litres of spray mix) on Apples and 1.25% (1.25L per 100 litres of spray mix) on Pears.

- The addition of Gro-Wet wetting agent at a rate of 0.1% (100ml per 100 litres of spray mix) is highly recommended and is expected to reduce the potential for excessive wetting and crop and leaf damage.

- Note that the Gro-Wet label contains a specific recommendation for use with Thin-It, but the current Thin-It label recommends no adjuvant additions. Do not apply Thin-It at full dilute water volumes when using Gro- Wet. Thin-It rate, maintain the rate per 100L of water.

- Thin-It spray application volumes should not over-wet tree foliage and visible runoff is not desirable. An ideal spray volume for late bloom removal is approximately half the runoff volume for the target canopy. Aim to apply between 500 (smaller dwarf trees) to 1,000 (larger traditional centre leader trees) litres per hectare when using in combination with Gro-Wet.

- DO NOT apply Thin-It if significant rain, or prolonged canopy wetness is expected within the next 48 hours or any rain within 8-12 hours. Apply under good drying conditions. Rewetting will reactivate the Thin-It and the risk of fruit and leaf damage can be significant.

- Thin-It is only expected to work on recently opened flowers that have yet to be pollinated – which will also be susceptible to fire blight. The Thin-It effect is to burn out the flower stigmas, which will also make them unreceptive to fire blight bacteria multiplication and infection.

- You should only need to apply Thin-It as a late bloom removal treatment when a fire blight infection period is forecast. Application should ideally be made 48-96 hours before an infection period.

- Consider applications of Thin-It on approximately seven-day intervals during fire blight risk conditions while late blooms are still emerging.

- Application using normal orchard sprayers using rates and volumes described above is expected to faster and safer than spot applications to blossom clusters by hand using a knapsack sprayer. Knapsack spraying is approximately 5-10X faster than hand removal, but there is a risk of over-wetting blossom clusters when using hand application methods, with increased risks of local leaf and fruitlet damage.

- In pears late blooms typically appear throughout the tree and full tree spraying would be recommended. In apples late blooms are more usually associated with one year old wood and the spray output can be biased to the tops of trees – with a proportional reduction in spray volumes (eg if just spraying the top half of dwarf apple trees spray volumes could be reduced to 250-300 L/ha).

- Always treat a small test area to gain confidence in the required application rates and volumes before committing to treating a large area.

Read and follow the Thin-It and Grow-Wet label recommendations and Grochem technical information for use of Thin-It prior to use.

DISCLAIMER: The information contained in this publication is of a general nature and should not be relied upon as a substitute for professional advice in specific cases. As no control can be exercised over the manner in which or the conditions under which this product is used, no responsibility will be accepted for any damage or injury whatsoever arising from the storage, handling, application or use of this product.

Clean water, hygiene and sanitation saves lives in Vanuatu

Three years on Grochem, Nordox and growers continue to support the UNICEF water sanitation and hygiene (WASH) in schools programme in Vanuatu that impacts the lives of 8,100 children and their communities.

The project today is seeing some real tangible outcomes but it hasn’t been without some major challenges since getting underway in 2016. The most significant being the Ambae volcanic eruption in September 2017 where 10,000 people were evacuated to Maewo Island, followed by a further full evacuation of the remaining residents in April 2018.

During this time all resources went into supporting the water and sanitation infrastructure of Maewo Island. This caused early setbacks for UNICEF to establish the clean water and sanitation project within many schools in the Penama region of Vanuatu, however things are looking up for the UNICEF project and the communities they’re working with.

On a recent trip to the Horticulture New Zealand conference, which has a specific focus on ‘Recognised Seasonal Employees’, held in Port Vila Vanuatu, Grochem General Manager Grant Morrish took the opportunity to speak with UNICEF water and sanitation specialist Emily Rand who commented – “just by having clean water close to the toilets would save children’s lives”.

UNICEF also shared some eye-opening statistics with us about the communities in Penama province Vanuatu including:

- Over 70% of schools water supply are in poor

- 68% of schools do not have functional hand washing facilities near toilets.

- 63% of schools report the water is not clean and

- Children are getting sick and miss out on or drop out of

- Without clean water and sanitation, the lives of children in Vanuatu are at

This year marks the third year of Grochem’s involvement with the UNICEF WASH project where Grochem and Norwegian company Nordox have donated a further $25,000. For every $1 raised for this project the New Zealand government, through the Ministry of Foreign Affairs and Trade, add an additional $4. This support super sizes the Grochem initiative to ensure real positive and tangible change can be made to the Vanuatu schools and communities of Penama.

In the past year, significant progress has been made. Currently each school is applying to the Vanuatu government for suitable latrines for their school. UNICEF provide the new latrines in kitset form complete with instructions; these are built by the local communities after training from a UNICEF led team. Several schools already have their new latrine blocks built and in use, with hand washing stations close by. The Vanuatu government and UNICEF relationship underpins this campaign and can not be underestimated for its continued success.

The UNICEF goal is for schools to have their new facility upgrades completed over the next three years.

The UNICEF approach is to set up systems and services whereby the communities can continue to benefit from the programme put in place and continue maintaining their infrastructure when the UNICEF resources are directed to other communities. Already UNICEF have seen an increase in school attendance rates, and combined with a strong emphasis on hygiene education has meant communities can now manage their own WASH facilities and future upgrades.

The UNICEF WASH project now includes increased disaster resilience with more schools able to be used for evacuation centres in times of emergency, meaning schools will be better prepared to withstand future disasters for both students and the surrounding community.

Grochem, along with Nordox Norway thank you for your continued support of the Nordox product. Your support enables us to provide the schools of Penama Vanuatu with safe water and clean sanitation facilities, and not just for today, but well into the future.

Classification change for Meteor

Meteor, a secondary thinning agent for apples from Grochem New Zealand, has received a well-needed classification revision from the Environmental Protection Authority (EPA). The reclassification results in a significant reduction in re-entry period on apple crops and the removal of an approved ‘certified handler’ requirement. This is a result of a slight reduction in the maximum allowable use per application, but with great benefits.

Re-entry time significantly reduced

Until now, the EPA had set a minimum re-entry period in New Zealand due to lack of data being available for Meteor relating to its use on apples. Grochem had independent studies completed for the EPA on residues from Meteor on fruit under local conditions.

The minimum re-entry period for Meteor was 28 days, which has now been significantly reduced to 1 day with gloves, and 4 days without gloves.

This is going to allow growers to continue orchard operations much sooner, including bringing in apple thinning crews earlier, enabling pest monitoring, leaf sampling and irrigation monitoring with just a few days of application.

Certified handler restriction removed

The reclassification sees Meteor change from a 6.1B to a 6.1D class, which removes the restriction of requiring a certified handler to manage Meteor. Grochem’s R&D Manager Iain Latter said the requirement of having a certified handler has been a challenge for growers using Meteor, so Grochem are pleased to see the two-year process reach such a result.

“Although the process has taken a significant amount of time, we’re pleased to finally see an outcome that removes barriers and issues for growers handling the product and allows them to get on with orchard operations” said Iain.

Maximum allowable use per application slightly reduced

With a small reduction in the maximum allowable use from 750g to 740g of Meteor per application (with two applications allowed), the reduction is small compared to the benefits gained for growers from the reclassification.

About Meteor

Meteor is a photosynthesis inhibitor which when applied to apple fruitlets will result in a reduction in fruit set. Fruit thinning is not universal, so result may vary with application rate, timing, variety, climate, canopy size, stress on the crop and with other thinning sprays applied to the block.

Meteor is a photosynthesis inhibitor which when applied to apple fruitlets will result in a reduction in fruit set. Fruit thinning is not universal, so result may vary with application rate, timing, variety, climate, canopy size, stress on the crop and with other thinning sprays applied to the block.

For more information and to view product label, safety data sheets, info sheets and product safety card, visit http://nz.grochem.com/products/meteor/

Quick check

Changes to Meteor classification

1. Re-entry significantly reduced – now one day with gloves and four days without.

2. Certified handler control – removed. Product has been reclassified to a 6.1D and is no longer 6.1B, so the need for certified handlers is removed.

3. Maximum allowable use – slightly reduced to 740g of Meteor per application (2 allowed)

Optimising six-spotted mite control and the use of ParaMite

This article originally appeared in the AvoScene March edition

The six-spotted mite (SSM) Eotetranychus sexmaculatus is native to central America and is thought to have been present in New Zealand since at least the 1950s.

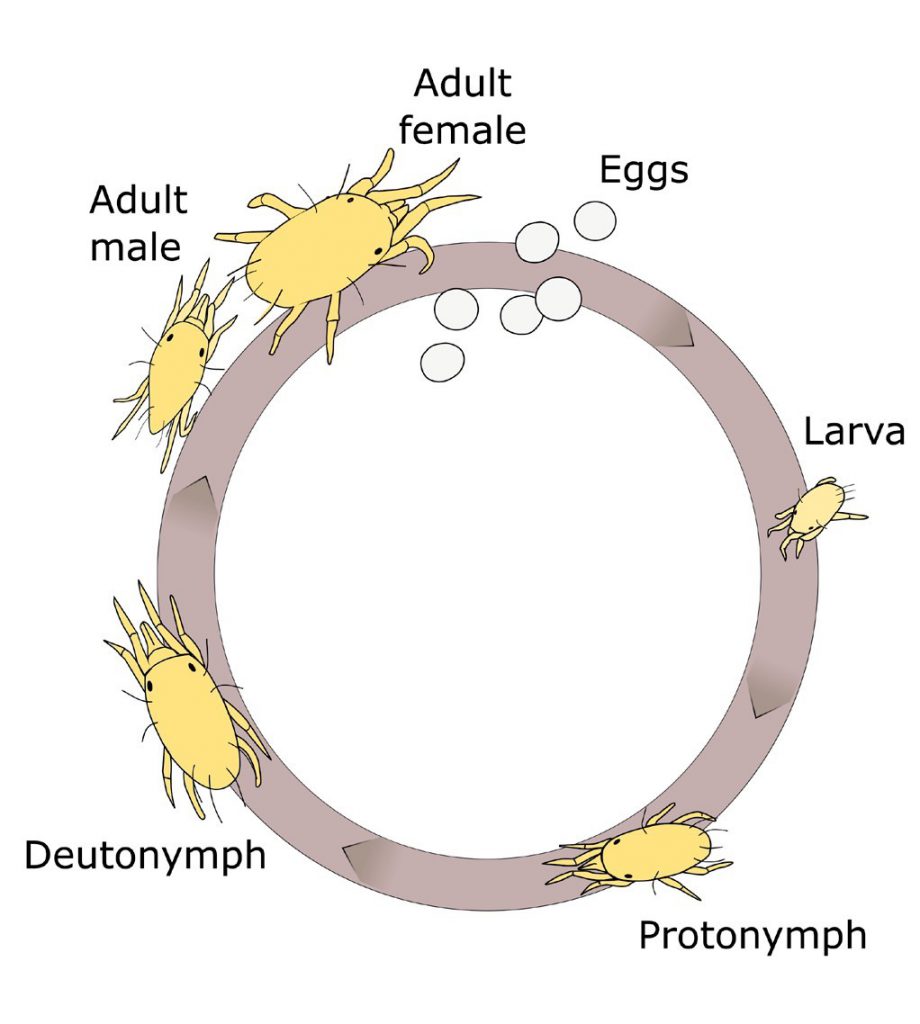

SSM levels can fluctuate through the season, so understanding its lifecycle and population dynamics can significantly help with decisions around when and what you might spray.

Rising temperatures significantly accelerate egg to adult development, so adult populations generally increase in spring and decline from January to March. Being able to predict patterns of egg hatch and seasonal abundance is therefore useful when determining the optimum time to apply control sprays.

Mites are always present in orchards and they hide very effectively within the canopy, producing multiple generations per year. Their distribution tends to be very patchy within an orchard and they do not move far unless they are disturbed by activity such as pruning.

An orchard with high levels of SSM, together with susceptible trees, will often require the use of targeted miticides to prevent defoliation. ‘Susceptible trees’ relates to the contributing factors that may predispose avocado trees to SSM population outbreaks including nutrient deficiency, heavy flowering, drought, high nitrogen levels or an abundance of alternative host plants.

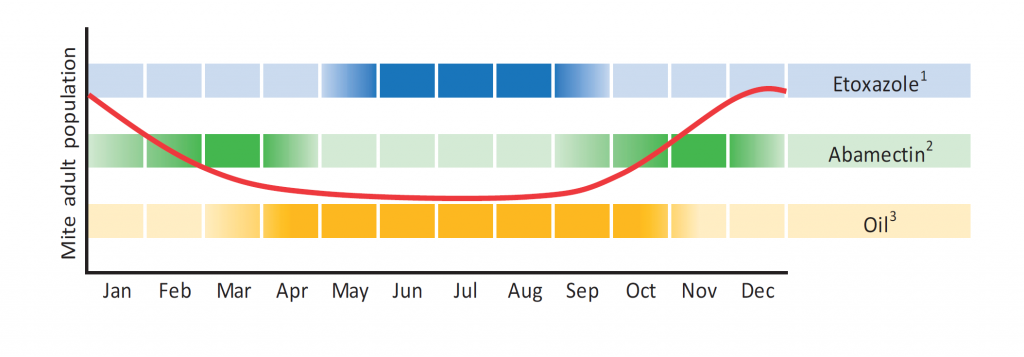

When Paramite (etoxazole) was introduced to New Zealand in 2011 for the control of SSM mite in avocados, it was a world-first registration. It quickly gained popularity and a key position in the avocado industry spray programme. Etoxazole is an insect growth regulator with translaminar activity. It is important however to understand how the product works to get the best out of the single application available to growers each year.

The specificity of etoxazole against spider mites does make it an excellent choice for IPM pest management. It has low toxicity to predator mites and is very safe for bees and ladybirds, although spraying while bees are active in your orchard is never recommended as the physical impact of the spray water alone can be detrimental to bees.

Etoxazole is reported to have translaminar activity, meaning the product will move through the leaf from contact point of the spray on the upper surface to the under surface of even mature leaves where mites are feeding. Other agrichemicals such as abamectin have more activity when immature leaf is present. Due to the residual activity of etoxazole on mature leaf, the product has an extended withholding period for some export markets. Etoxazole has been found to best suit winter use periods. Abamectin, with a shorter withholding period and good activity when flush is present, is often a more suitable product closer to harvest.

Insect growth regulator sprays are very effective yet generally slower acting than knock down chemicals. They work either by mimicking key growth hormones or directly affecting cuticle formation or other essential growth processes. Often these chemicals will inhibit insect moulting, some can kill eggs directly and may even sterilise adults so laid eggs will not hatch.

The range of activity of etoxazole against the whole lifecycle greatly extends the period of effective control compared to other miticides products. It stops mite population development in its tracks. It is effective

at all stages of the mite lifecycle. It is ovicidal, having excellent contact activity against eggs, and inhibits the moulting process all of the larvae and nymphs stages of mite development. It has limited activity on adults but sterilises adult females. Adults will be present for up to a couple of weeks after application, feeding and causing damage.

Etoxazole use is limited to one application per year to ensure we do not get resistance. However, a single application is not persistent enough to control multiple generations of mites; often control is seen over a couple of months, but it is not a full year solution and a full season programme with other agrichemicals is required.

A miticide programme over the year should therefore include the use of agrichemicals with other modes of action such as mineral oil or abamectin. Where there are high populations of adults, incorporating a knockdown miticide into the spray programme is also recommended.

Use of a product containing mineral oil or abamectin, 14 days prior to using etoxazole, may extend the period of control due to their knockdown effect on adults. Note AvoGreen monitoring does not distinguish between adult SSM and nymphs.

Coverage is still very important as translaminar activity is not systemic, and most of these products do not move around the entire tree. No oils nor other surfactants are required to enhance uptake of etoxazole and no trial work has demonstrated any benefit from the addition of oil or surfactants, and in some cases this may extend the residue decay timelines.

Iain Latter R & D Manager, Grochem

Glenys Parton, Industry Systems Manager, NZ Avocado

Brad Siebert, Biosecurity and Programme Manager, NZ Avocado